技术文章 / Technical articles

表面张力仪的选购主要注意如下几点:

1、测试原理:测试原理决定了其测试功能以及测值精度。目前基于称重原理的白金板法为第三代基于Young-Laplace方程修正的白金板法,其特征为板一接触到液面后即停止,此时动态修正接触角值和浮力值。此方法可用于测试动态表面张力(取决于分析天平速度)以及测试表面活性剂和有粘度样品的表面张力值。

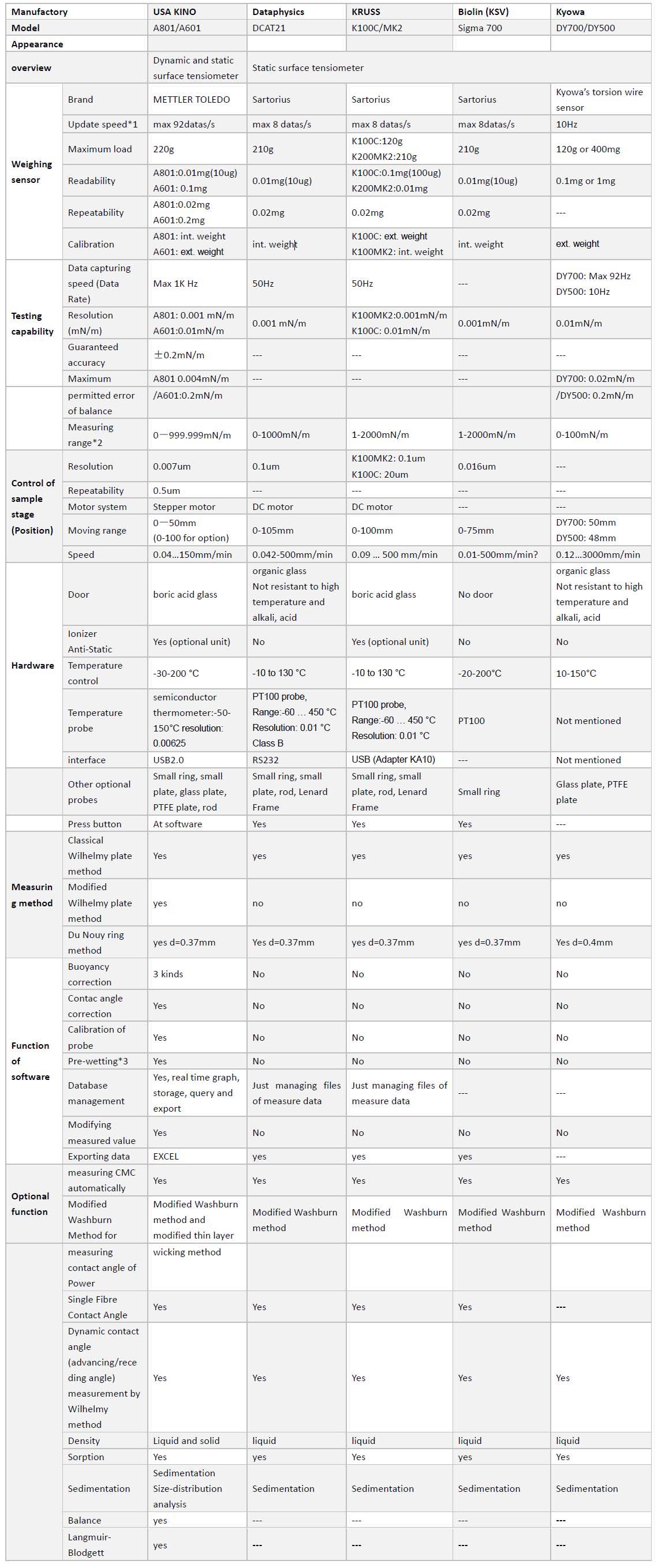

There are a lot of surface tensiometers with different measuring methods, made by different manufactories. And quality and working accuracy of these surface tensiometers are quite different from each other. How to choose the most suitable surface tensiometer for us is more important. This article will show you how to begin your surface tension measuring experience by choosing the most suitable surface tensiometer from different manufactories in worldwide.

Selecting surface tensiometer is easier than choosing suitable contact angle meter, because weighing sensor (main unit of meter) is almost fixed into balance made by such manufactory as METTLER TOLEDO and Sartorius. So, surface tensiometers made by different manufactories are homogenized very much. There are five main manufactories include KINO, KRUSS, Dataphysics, Biolin (Attension, KSV), Kyowa around world. All most all of them except KINO measured surface tension of liquid (or mixture liquid) using classWilhelmy plate method. (Referhttp://www.uskino.com/news/55.html)

1, Startup choosing surface tensiometer (tension meter) from measuring method of surface tension?

Referring http://www.uskino.com/news/55.html for more information about method.

here are main commercial tensiometer includes max bubble pressure tensiometer, max drop volume (max drop weight) tensiometer, optical tensiometer (drop shape analysis system based on pendant drop method or sessile drop method) and force surface tensiometer based on weighing method. First two tensiometers are always used to measure dynamic surface tension (perhaps with poor measuring accuracy of surface tension). Among them, max bubble pressure tensiometer is more common. But recently, scholars start to use optical tensiometer based on oscillating method to measure dynamic surface tension and experiments show that better results can be achieved than first two. But measuring accuracy of optical tensiometer is about 1-2%. It is worse than force surface tensiometer ( About ±0.2mN/m or dyne/cm).

So, in this article, we discuss how to choose force surface tensiometer only. You can find how to choose tensiometer based on other methods in our web.

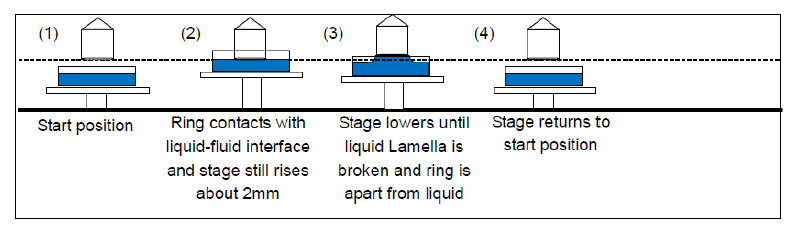

There are two main measuring methods including Du Noüy ring method and Wilhelmy plate method for force tensiometer.

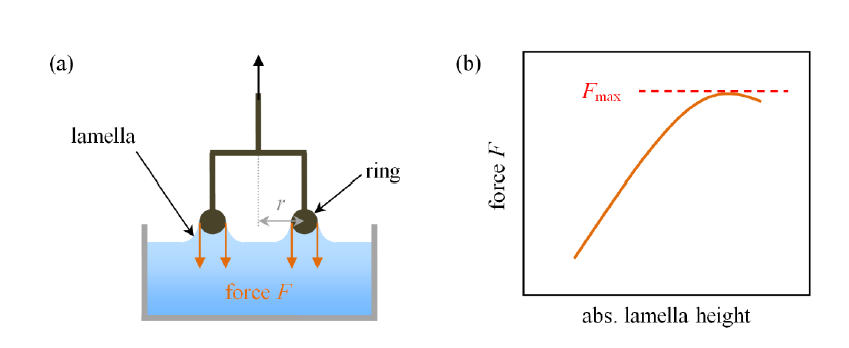

Du Noüy ring method

Du Noüy ring method is so popular and almost all manufactories consider this method as gift when they sale tensiometer. Almost all manufactories can provide this method in their tensiometer. And measuring process or Du Noüy ring method is almost same. Nobody can enhance measuring accuracy of Du Noüy as high as Wilhelmy plate method due to such inborn defect as:

- Liable to be deformed

- Hard to keep levelness of ring for Du Noüy method.

- And more important disadvantage of Du Noüy ring method is it cannot be used to measure surface tension of viscous sample such as glycerol and adhesives.

Main reason of it is same as class Wilhelmy plate method as shown below. More precise method for force tensiometer is Wilhelmy plate method. If you want to choose tensiometer just based on Du Noüy ring method, we think that it will mislead you. But when you are budget shortfall for surface tensiometer, you can choose Du Noüy ring tensiometer such as surface tensiometer model A3 that is used balance from KINO or tensiometer made by Fisher.

Cheaper tensiometer: left one is Classical Du Noüy ring Tensiometer used torsion wire sensor, middle one is tensiometer made by fisher and right one is tensiometer model A3 made by KINO which used balance as sensor. Please be noted that KINO is only one that provides tensiometer at price about 1500USD using balance.

There are several variations of the Wilhelmy plate methods. All are based on balancing the static forces of surface tension, gravity, and buoyancy acting on a thin plate (usually made of glass or platinum) suspended vertically in the air-liquid interface.

Four variations of the Wilhelmy plate measurement are commonly used:

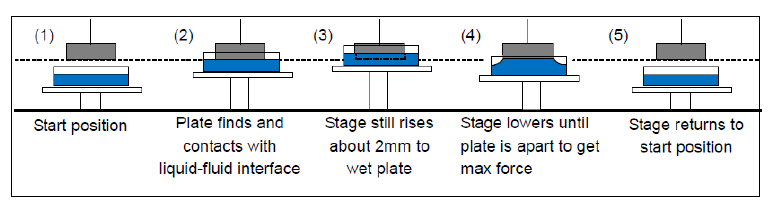

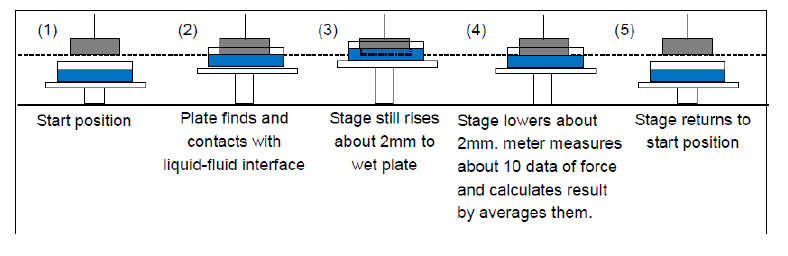

- The zero-buoyancy method (Kawanishi et al. 1970; Lane and Jordan 1970): plate was immersed and withdrew and was kept stationary at zero depth of immersion. Then, measuring force of tension and calculating surface tension from equation. Generally, we will measure about 10 value of surface tension versus time and average them, and we will consider this averaged value as final value.

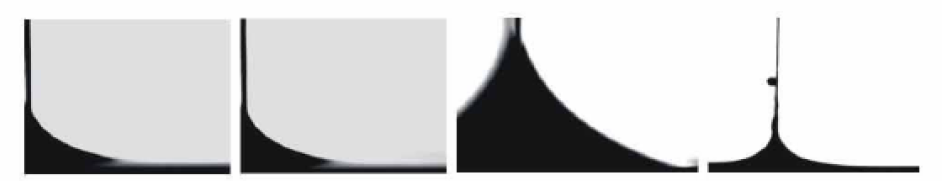

- The detachment method (Furlong and Hartland 1979): the plate is quasi-statically pulled up until it is entirely free from the liquid ( detachment mode). As the instant of breaking loose is well-defined, the force at that moment can be rather easily determined.

- The immersion method (Gaines 1966): Plate is immersed below interface of liquid-gas or liquid-fluid at a constant position such as 1mm, and correcting buoyancy from calculating buoyancy by this height and side of plate.

- The maximum-pull method (La Mer and Robbins 1958; Loglio et al. 1976; Gaonkar and Neuman 1984): Plate is pulled up until max value is gotten. In this method, plate is not pulled up quasi-statically and meniscus may be ruptured before Wmax reached.

Referring http://www.uskino.com/news/55.html for more information about method.

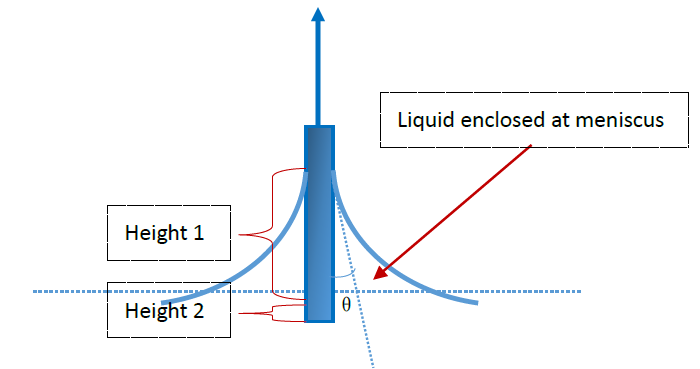

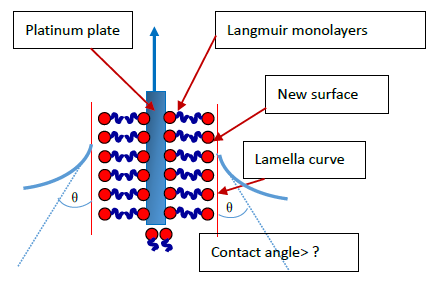

Recently, KINO proposed a new method name modified Wilhelmy plate method. What separates them from four method described above is we consider buoyancy and contact angle is always existing during measuring process. Please be noted that contact angle is not regard as 0°here because we find out that contact angle is about 29-32° in measuring process of surface tension (liquid-gas system). This will reduce value of surface tension about 1-3mN/m for measurement of surface tension.

Meniscus curve at interface of liquid-gas (fluid)-plate: 1, alcohol-air-platinum/iridium plate; 2, water-air- platinum/iridium plate; 3, benzene-water- platinum/iridium plate; 4, n-butyl alcohol-water- platinum/iridium plate

And, there exists influential buoyancy due to liquid enclosed at meniscus. So, how to correct this buoyancy is more important. This value is about 0.59mN/m (using plate with width 24mm and thickness 0.15mm, height of meniscus is about 8mm). Changing of height about 1mm will affect surface tension value about 0.07mN/m and it is about sensory force for 0.1mg balance (0.1mg ≈ 0.02mN/m)

Main different of classical and modified Wilhelmy plate method includes:

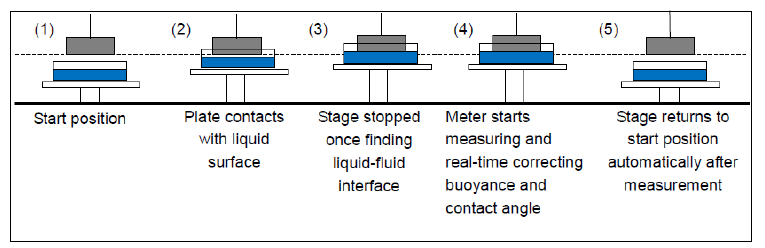

- Moving of sample stage: Classical Wilhelmy plate method will immerse plate into liquid about a height and then withdraw plate by same height, and measure surface tension by averaging several surface tension versus time (usually about 10 datas); But modified Wilhelmy plate method will not immerse and withdraw the plate. In this method, sample stage will stop once finding interface of liquid-gas or liquid-fluild.

- Calculating equation: Classical Wilhelmy plate method used simplified equation without buoyancy and contact angle (this value is assumed as 0°). But, in modified Wilhelmy plate method, buoyancy and contact angle should be corrected by Young-Laplace equation or elasticity coefficient.

Diagram of different measuring methods of surface tensiometer

Note:This method is used in surface tensiometer made by Kruss, KSV, KYOWA. And it cannot used to measure surface tension of cationic surface active agent and sample with viscosity due to its immersing and drawing out process.

Note: Sometimes, we will repeat process 2, 3 after process 3 by rising stage and lowering stage several times, and calculate surface tension by average measured data.

You can visit youtube to watch videos of surface tensiometer from different manufactory by click address below:

Surface tensiometer model K100 from Kruss:

http://www.youtube.com/watch?v=-R24A5KaCuc

surface tensiometer model sigma 700 from Attension

http://www.youtube.com/watch?v=mwUBemTAHj0

surface tensiometer model DY300 from Kyowa

http://www.youtube.com/watch?v=MkKlJ-2YrqA

surface tensiometer model A601 from KINO

http://www.youtube.com/watch?v=yTpWg-btpAE

1.2.4.1 Both Wilhelmy plate method and Du Noüy ring method is not suitable to measure interface tension between liquid-fluid system.

Measurement of the interfacial tension between two immiscible liquids can present special difficulties. Measurement by the capillary rise, Du Noüy ring, or Wilhelmy plate method is problematic in that the contact angle is often nonzero (from 20-120°). The pendant drop and drop weight methods can both be applied, provided the densities of the two liquids are sufficiently different. The pendant drop method, in particular, is widely used for interfacial tension measurement. Ultralow values of interfacial tension can be measured by the spinning drop or pendant drop methods. (Refer “Measurement, Instrumentation, and Sensors Handbook, Second Edition, Spatial, Mechanical, Thermal, and Radiation Measurement, Edited by Halit Eren, CRC Press 2014, Pages 1–14, Print ISBN: 978-1-4398-4888-3, eBook ISBN: 978-1-4398-4889-0, DOI: 10.1201/b15474-52.”)

Because when plate or ring immersed and withdrew from viscous sample, adhesive force will affect at probe during movement of plate or ring and this force cannot be corrected by any way. So, usually when we used tensiometer based on classical Wilhelmy plate method or Du Noüy ring method, measured result will larger than actual value.

Secondary, it is difficult to immerse plate or ring into sample with high viscosity. So, measurement cannot be carried out at this case.

But with modified Wilhelmy plate method, you can measure surface tension or viscous sample and max viscosity can reach 10,000CP.s.

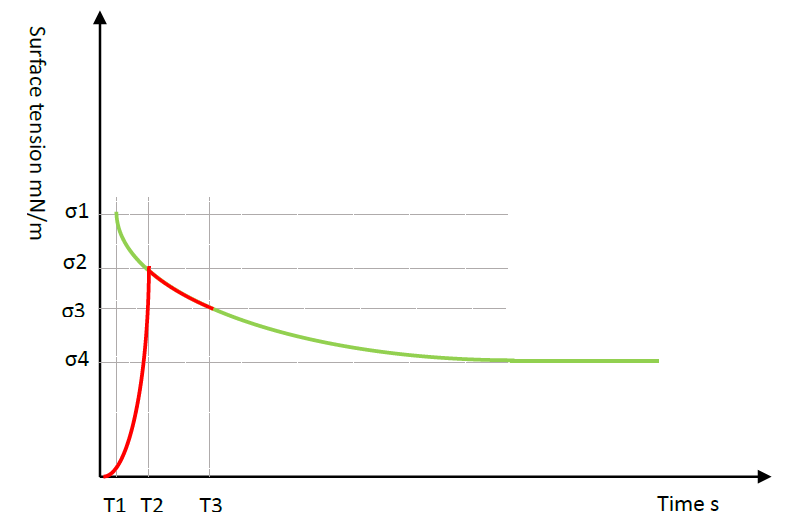

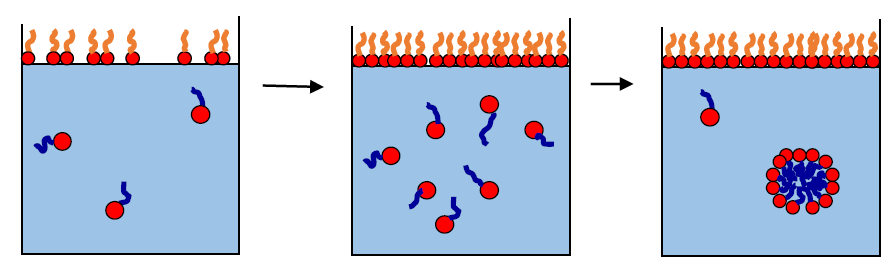

When measuring surface tension of surfactant based on classical Wilhelmy plate method, contact line between liquid and plate is keeping moving and will age new surface of surfactant. So, when we used classical Wilhelmy plate method to measure surface tension, if moving time and total measuring time is not agree with adsorbing time of surfactant to contact line, we may not achieve real value of sample’s surface tension. And usually, measured value is higher than actual one.

Red line means changing value of weighing during measuring process and green line means changing value of surface tension during adsorbing process. So, if at time T3, surfactant has not adsorbed totally to contact line between liquid-plate, measured values will be entirely higher than actual one.

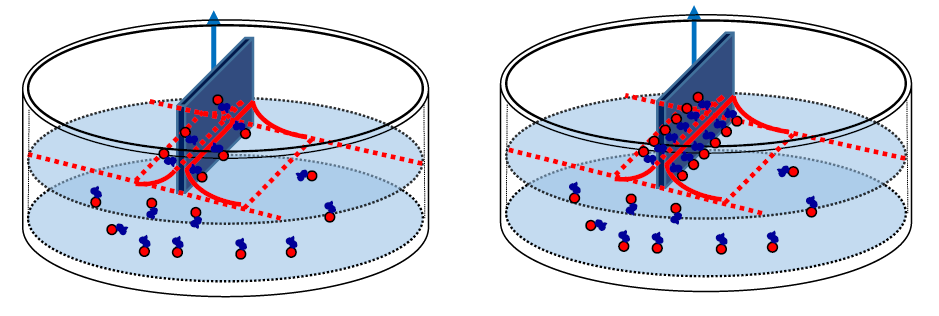

By contrast, in modified Wilhelmy plate method, surfactant will adsorb at interface between liquid and gas at first and adsorbs to contact line once plate touching interface, and will keep on adsorbing until contact line is full of surfactant as shown above. You can find out measuring process is quite agree with adsorbing process of surfactant.

We have measured value of some surfactant, and find out that when measuring surfactant with longer adsorbing time, measured value used classical Wilhelmy plate method or Du Nouy ring method is much higher than modified Wilhelmy plate method. And we check out measured value measured by modified Wilhelmy plate method using pendant drop method and spinning drop method, all values are agree with each other.

Unit: mN/m

|

No. |

name |

type |

Classical Wilhelmy plate |

Du Nouy ring |

Modified Wilhelmy plate |

Pendant drop |

Spinning drop |

|

1 |

Diallyldimethylammonium chloride(1827) |

cationic |

38.6 |

37.5 |

29.1 |

31.5 |

31.8 |

|

2 |

Dimethyldioctadecylammonium chloride(1821) |

cationic |

39.4 |

36.5 |

19.5 |

21.6 |

22.3 |

And more over, as KRUSS proposed, when measuring surface tension using Wilhelmy plate method, Langmuir monolayers made at surface of plate during measuring process. Especially when measuring surface tension of surface active agent, this new surface of monolayers will change surface of probe into hydrophobic surface, and this is not suitable for measurement of surface tension because contact angle here is no longer 0°. (Refer application article “Influences to Plate measurements” from KRUSS.)

Because probe should be immersed into liquid in Classical Wilhelmy plate method or Du Noüy ring method, you must keep a height of liquid (such as 5mm?) to carry out measurement of surface tension. But in modified Wilhelmy plate method, plate should not be immersed in and we have invented a sample vessel made of PTFE to measure surface tension of liquid using volume about 1mL.

If viscosity of your sample is higher than 500CP.s, classical Wilhelmy plate method and Du Nouy ring method is not your suitable choice. You can choose KINO’s tensiometer used modified Wilhelmy plate method or optical tensiometer based on pendant drop method or constrained sessile drop method. A simply way to adjusting whether your sample is suitable for using modified Wilhelmy plate method to measure surface tension is checking out if liquid is movable by inclining sample bottle. If sample is easy to move, you can use modified Wilhelmy plate method to get more accurate value of surface tension. If not so, this sample can only be considered as solid and using method of calculating surface free energy of it based on equation of state method.

Contact us for comparing value of different viscosity that measured by different method.

2.2 Measuring surface tension and critical micelle concentration (CMC) of surfactant

If your budget is enough to buy automatic critical micelle concentration measuring system (syringe pump system and corresponding controlling software), you can purchase one for you. But, using effect may be not as good as you supposed. We suggest you choosing measuring CMC by manual to find a proper concentration and then allocating several sample with concentration nearby CMC measured by manual to measure CMC more accurately. Such operations described above is instead more convenient and timesaving.

For most cases of measuring surface tension of surfactant, all of three methods can be used, except measuring surface tension of surfactant with long adsorption time.

Another phenomenon that we must pay attention is when measuring surface tension of surfactant, measured value will be reduced at about 0.2-0.5mN/m each step. This is caused by Langmuir monolayers described above. So, when measuring surface tension of surfactant using tensiometer based on Wilhelmy plate method or Du Nouy ring method, repeating measurement more than 5 time is not proper. We advise you to measure surface tension by repeating about 3 time. Or, you can stir sample and clean plate or ring, then measure surface tension. Value of surface tension will return to value you just measured.

2.3 Your budget?

As you known, you get what you pay for.

|

No. |

Range of budget |

type |

Manufactory |

Note |

|

1 |

About 1,000-2,500 |

Model A3 |

KINO |

Balance 1mN/m |

|

CSC |

CSC |

torsion wire |

||

|

K6 |

Kruss |

torsion wire |

||

|

2 |

About 4,000-16,000 |

A101 |

KINO |

Balance 0.1mg |

|

A601 |

KINO |

Balance 0.1mg |

||

|

Sigma 702 |

Biolin |

torsion wire |

||

|

DCAT11 |

Dataphysics |

balance |

||

|

K11 |

Kruss |

balance |

||

|

DY-300 |

Kyowa |

torsion wire |

||

|

3 |

20,000-60,000 |

A801 |

KINO |

Balance 0.01mg |

|

Sigma 700 |

Biolin |

Balance 0.01mg |

||

|

K100 |

Kruss |

Balance 0.1mg (K100C) and 0.01mg (K100MK2) |

||

|

DCAT21 |

Dataphysics |

Balance 0.01mg |

3, Difference of surface tensiometer made by different manufactory.

Note:

1, Test method of update speed of balance is acquiring data from balance versus times about several seconds, and at same time, we used stopwatch to record times; after then, calculating speed of data updating by dividing number of data by time. And we find out that data update speed of Sartorius’s balance model WZA215 can only reach’s speed about 8-10 data/s when we using code “print: 1B 50 0D 0A”. If we used function of “Auto output on” at Sartorius’s balance model WZA215, update speed is about 20data/s, but we cannot control balance such as stop data outputting or power off, balance will continue to outputting data without control.

2, Max capability depends on max load of balance. So real range of max value is higher than 1000 or 2000mN/m. But when we used torsion wire sensor in tensiometer, max reload of sensor is just max capability in this sensor.

3, Pre-wetting is very useful when measuring surface tension of organosilicone surfactant or fluorine surfactant.